What Are Centrifugal Fans and Why Are They Essential?

Centrifugal fans, also known as radial fans, are designed to move air or gases using centrifugal force. These fans draw air into the center of a rotating impeller and then expel it at a 90-degree angle through the outlet. This unique mechanism allows them to generate high-pressure airflow with consistent volume, making them ideal for industrial, commercial, and heavy-duty applications.

From manufacturing plants and workshops to HVAC systems and warehouses, centrifugal fans are critical for maintaining clean air, cooling equipment, and regulating temperature.

Key Features of Centrifugal Fans and Blowers

High-Pressure Output

Centrifugal fans produce powerful airflow, making them suitable for applications that require air to travel through long ducts, filters, or systems with resistance.

Durability Under Harsh Conditions

Built with corrosion-resistant metals and industrial-grade components, these fans are made to perform in environments with dust, heat, and moisture.

Energy Efficiency

Despite their power, centrifugal blowers are highly efficient. Their backward-curved impellers reduce energy waste while maximizing airflow.

Versatile Mounting and Integration

Available in multiple sizes and configurations, they can be wall-mounted, ducted, or integrated into ventilation systems without major retrofitting.

Common Applications of Centrifugal Fans

Commercial Ventilation

Used in kitchens, warehouses, and office buildings to maintain clean air and reduce humidity.

Dust Extraction and Filtration

Essential in workshops, woodworking shops, and factories to remove airborne particles and maintain safe air quality.

HVAC Systems

Centrifugal fans are key components in heating and cooling systems, where consistent and controlled airflow is critical.

Cooling for Industrial Machinery

Used to extract hot air and prevent equipment from overheating in demanding production environments.

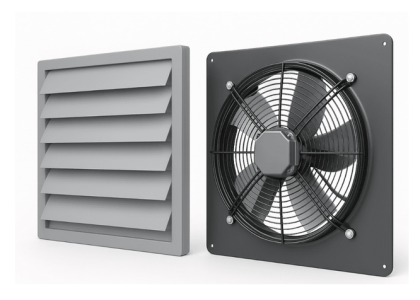

Types of Centrifugal Fans Available at Fan Movement

Single Inlet Centrifugal Fans

Compact and efficient, these draw air from one side of the impeller and are ideal for targeted duct systems or confined spaces.

Double Inlet Fans

Provide greater volume and flow, with air drawn from both sides. Best suited for HVAC and large ventilation systems.

Backward-Curved Impeller Fans

Engineered for quiet operation and high efficiency. These fans are commonly used in clean-air systems and precision environments.

Forward-Curved Impeller Fans

Offer high airflow at lower pressures. Ideal for smaller systems or spaces with minimal duct resistance.

Product Highlight: High-Pressure Centrifugal Blower

This industrial-grade blower is engineered for demanding commercial environments. Key features include:

- Galvanized steel housing for corrosion resistance

- Dynamically balanced impeller for low vibration

- Motor options for single-phase and three-phase power

- Mounting brackets are included for flexible installation

- Airflow capacity up to 2,500 m³/h

Designed for continuous operation and high-reliability airflow in mission-critical applications.

Fan Movement – Industrial Performance, Local Expertise

Fan Movement is proud to supply high-performance centrifugal fans and blowers that meet the airflow challenges of South African businesses. Whether you’re building a new ventilation system or upgrading existing infrastructure, our products are selected for their durability, efficiency, and ease of installation.

“Move more than air. Move forward with confidence.”