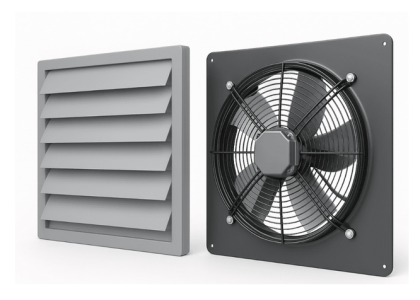

Why Bifurcated Fans Are Essential

Ventilating air contaminated with fumes, high temperatures, or chemical particulates requires a fan that can isolate its motor from the airstream. Bifurcated axial fans are built exactly for this purpose. Their design directs airflow around the motor housing rather than through it, allowing safe operation in harsh industrial environments.

Industries such as chemical manufacturing, metal processing, and fume extraction benefit from this design, where conventional fans would quickly overheat or fail due to direct contact with corrosive or hot air.

Key Features of Bifurcated Axial Fans

- Motor Isolation Design

The motor is mounted in a separate compartment outside the airstream, protected from heat and fumes. This extends motor life and reduces maintenance frequency. - High-Temperature Performance

These fans are suitable for air streams reaching up to 200°C or more, depending on the motor and impeller configuration. - Corrosion-Resistant Materials

Casing and impellers are often built from galvanized steel, stainless steel, or aluminium, depending on the corrosive nature of the application. - Flexible Mounting Options

Available for horizontal or vertical installation with flanged ends for easy integration into duct systems.

Common Applications of Bifurcated Axial Fans

- Chemical fume extraction in production plants

• High-temperature air movement in kilns or ovens

• Foundry ventilation systems

• Exhaust ventilation in hazardous material handling areas

• Paint booth and solvent room exhaust systems

How to Choose the Right Bifurcated Fan

- Identify the temperature range and chemical composition of the air you need to extract.

• Confirm your ducting system diameter and required airflow (measured in m³/h).

• Choose the appropriate impeller material and motor insulation class (e.g., Class H for high heat environments).

• Ensure compatibility with variable speed drives for dynamic flow control.

• Consider IP ratings and motor protection based on your site’s exposure conditions.

FAN MOVEMENT – Built for Demanding Ventilation Environments

At Fan Movement, we offer bifurcated axial fans that combine safety, durability, and high performance. Engineered for the toughest South African industrial conditions, our fans ensure uninterrupted ventilation in environments where heat, fumes, and contamination present daily challenges.

We work closely with engineering teams, site managers, and facility operators to specify the right model for your application.

“Engineered to handle what others can’t.”