Inline tube fans have become a game-changer in the world of industrial airflow and ventilation. Their compact design, high performance, and energy efficiency make them an ideal choice for industries seeking effective ventilation solutions.

In this article, we’ll explore what makes inline tube fans so effective, how they work, their key benefits, and the various applications where they excel.

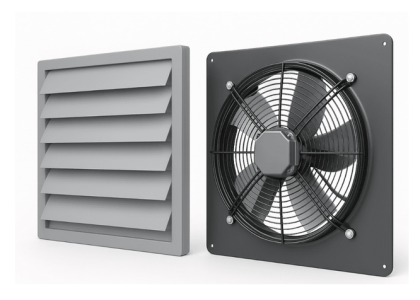

Compact Design

One of the standout features of inline tube fans is their compact design. Unlike traditional fans that can be bulky and occupy significant space, inline tube fans are designed to fit seamlessly within ductwork systems. This space-saving feature is particularly beneficial in industrial settings where maximising floor space is crucial. Their cylindrical shape allows for easy installation within existing duct systems without the need for extensive modifications.

High Performance

Don’t let their size fool you; inline tube fans pack a punch when it comes to performance. They are engineered to move large volumes of air efficiently, making them suitable for various industrial applications. Whether it’s removing warm and stale air, bathroom smell, these fans ensure reliable and consistent airflow.

Energy Efficiency

In today’s industrial landscape, energy efficiency is more important than ever. Inline tube fans are designed with this in mind, consuming less power while delivering optimal performance. Many models utilise advanced motor technologies, such as electronically commutated (EC) motors, which offer superior efficiency compared to traditional AC motors. This not only leads to significant energy savings but also reduces operational costs, making them a cost-effective solution for businesses.

Versatility

Inline tube fans are suitable for a wide range of applications across various industries. In industrial settings, they are used for process ventilation, heat control, and removing contaminants from the air. Their ability to handle long duct runs with minimal loss of pressure makes them ideal for complex ventilation systems. Additionally, their quiet operation ensures minimal disruption, which is essential in environments where noise control is a priority.

Improved Air Quality

Maintaining good air quality is crucial in industrial environments to ensure the health and safety of workers. Inline tube fans play a vital role in this by effectively removing pollutants, stale air, and excess heat, replacing them with fresh air. This continuous exchange of air helps in maintaining optimal indoor air quality, contributing to a healthier and more productive work environment.

Easy to Maintain

Maintenance is a critical consideration in industrial equipment selection. Inline tube fans are designed for easy maintenance, with many models featuring accessible components that simplify cleaning and servicing. This ease of maintenance ensures long-term reliability and performance, reducing downtime and associated maintenance costs.

At Fan Movement, we know how important good airflow is for keeping your workspace comfortable, efficient, and safe. That’s where inline tube fans come in—they’ve completely changed the game when it comes to industrial ventilation! These fans may be compact, but they pack a serious punch when it comes to performance, energy efficiency, and versatility. Whether you’re looking to improve air quality, reduce energy costs, or just keep things running smoothly, inline tube fans are a smart, cost-effective choice.